Are you struggling with inventory-related obstacles like overstocking and understocking every year?

Do you feel like you're losing control of your stock?

Are you a small business owner facing these challenges? Don’t worry—there’s a solution!

Inventory counting! It helps you track your business status and optimize inventory management.

Every small business needs this mantra to climb the ladder of success in the future.

This article will guide you through inventory counting and small business inventory management.

Let’s see how it goes!

Inventory count is the process of physically counting and recording the quantity of items a business has in stock.

This means systematically checking each item in a company's inventory against its recorded amount to identify any discrepancies, such as missing or surplus items.

This task is crucial for businesses to ensure accurate financial records, assess stock levels, and prevent errors like overstocking or stockouts. Inventory counting is usually performed by using tools like barcode scanners or manual counting methods.

Now that we understand inventory counting, let’s see why it’s essential for small businesses. The answer is simple! When you conduct regular inventory counts, you can optimize operations, reduce financial inaccuracies, and make informed purchasing and sales decisions aligned with small business trends.

It is like conducting a real-time evaluation of your stocks!

Moreover, inventory counting is highly important for maintaining the efficiency and profitability of a business's supply chain.

Discover small business stock count rules.

Regular inventory counts help small businesses manage stock more efficiently. Let’s see how.

You know when consistently counting their stock, businesses can keep track of what they have on hand and identify any discrepancies or problems, like overstocking or shortages. This allows them to adjust their ordering and stocking levels accordingly. On the other hand, it helps small business stock control and prevent unnecessary expenses or lost sales.

Additionally, regular inventory counting helps businesses make more informed decisions about purchasing and selling. This helps small businesses improve inventory management and boost long-term profitability.

It is evident that regular inventory count is the first step for small businesses to optimize their operations and maximize their success.

Explore Inventory Management Techniques for Small Business.

What is the most important formula to run a successful business?

Customer satisfaction, right?

Regular counting ensures businesses have the right products available when customers order. This prevents delays, reduces backorders, and speeds up order fulfillment.

Furthermore, if businesses can avoid stockouts or overstocking situations, they can meet customer demand more effectively. This will improve overall satisfaction.

When customers receive their orders promptly and accurately, they are more likely to be satisfied with the service provided. Don’t you think so?

It actually leads to increased loyalty and positive word-of-mouth referrals for the business.

Discover 10 Effective Strategies to Elevate Customer Satisfaction.

Another reason why regular inventory counting is essential for small businesses is to forecast demand accurately.

Now let’s see what this means.

When they consistently monitor their stock levels through inventory count, businesses can identify patterns and trends in product sales. This data helps them anticipate future demand more effectively, allowing them to adjust their inventory levels and procurement strategies accordingly.

For example, if certain products consistently sell out quickly during specific times of the year, businesses can order more stock in advance to meet anticipated demand.

This is a solid method to stay ahead of demand fluctuations. This way, small businesses can ensure they have the right products available when customers need them.

The ultimate result is improving customer satisfaction through maximizing sales opportunities!

Explore demand forecasting: 5 steps to improve your skills.

When you run a small business, you are required to have a balance in your cash management.

For this also, inventory counting helps a lot. Don’t you believe it? Well, let us explain how this happens.

Frequent stock checks help identify inefficiencies like overstocking or shrinkage and prevent unnecessary costs. With accurate inventory data, you can optimize your purchasing decisions.

This means you can order only what is needed!

It drastically reduces excess inventory carrying costs. Moreover, when minimizing stockouts through better inventory management, businesses avoid potential revenue losses from missed sales opportunities.

This is why it is vital to adhere to diligent inventory counting practices. With the right approaches to inventory count, small businesses can streamline operations, control expenses, and ultimately improve their bottom line.

As you can see, right small business inventory management equals proper cash management.

Discover Secrets to Mastering Cost Management & Efficiency: Tips for Businesses.

How can you be sure there is no theft happening in your business?

This is why you need to perform an inventory count in the first place.

Regular stock checks help detect discrepancies between recorded and actual inventory.

This helps to uncover potential instances of theft or unauthorized use of inventory. Moreover, by maintaining accurate records of inventory movements, businesses can hold employees accountable for any discrepancies and implement tighter security measures to deter theft.

This strategic approach safeguards your assets, minimizes financial losses, and builds trust within your business ecosystem.

To begin inventory count for small businesses, first, you have to create a comprehensive list of all inventory locations.

This step is crucial as it ensures no area is overlooked during the counting process.

This list improves planning, prevents errors, and ensures thorough inventory checks.

By identifying every storage space, from shelves to warehouses, businesses can allocate resources effectively and simplify the counting process. Moreover, having a complete list minimizes the risk of missing items or double counting, leading to more accurate inventory records.

As you can see, this is a good point to start your inventory count. Having a thorough inventory location list establishes a solid foundation for successful inventory management and helps businesses maintain organized and efficient operations.

And you can make sure no location is missed!

After listing inventory locations, the second step for small businesses is to enumerate each item in their inventory.

This step ensures no items are overlooked during counting. When you list every item, you can accurately track stock levels, identify discrepancies, and make informed decisions about purchasing and sales by formulating small business stock control.

This approach establishes inventory organization and reduces errors, leading to better inventory management.

There are many ways to carry out this task. However, easy ways to accomplish this include using inventory management software, spreadsheets, or manual logs.

You can start with a detailed item list as it expedites the counting process and promotes efficiency.

This is the third stage, and it is crucial for efficient small business inventory management.

Grouping similar items together helps simplify the counting process, making it easier to track and manage inventory. Categorizing by type, size, or use helps identify patterns, assess stock, and make better restocking decisions. That’s the most important part of this.

On the other hand, it drastically reduces counting time, which is quite beneficial.

Businesses can categorize items manually or use inventory management software to ensure accuracy and effectiveness.

No matter what path you take, categorizing inventory encourages smoother operations and enhances small business stock control in the end.

Why is this needed?

The answer is when you go with unique descriptions, it helps distinguish between similar items and reduces the risk of confusion or errors during counting.

Detailed descriptions help employees identify products, their attributes, and their usage. This enables better organization and decision-making for sure.

Now let’s focus on how you accomplish this task. It is not very complicated. When you create unique descriptions, you can include relevant details such as product name, size, color, and any distinguishing features.

Yes, basically, you are noting down the uniqueness of the product!

You should not avoid this stage as clear and specific item descriptions expedite your inventory processes. It also ensures businesses maintain precise records and effectively meet customer demands.

Discover 10 inspiring product description examples and expert tips for crafting the perfect copy.

If we look into the requirement of generating barcodes or QR codes for each item in inventory count we can see it is vital for efficient tracking and management, especially in the small business framework.

Did you know that these codes provide a unique identifier for each product? It reduces the chance of errors and encourages faster and more accurate counting.

'Do I need software for this? '

Well, it is good if you have software, but don’t worry if you don’t have one yet.

Even without software, small businesses can create barcodes or QR codes using free online generators and print them on labels.

Scanning codes prevents manual errors and updates inventory records in real time. Furthermore, we can see using barcodes or QR codes enhances inventory control for small businesses as it reduces chances for errors.

Discover on A small business guide to setting up a barcode tracking & inventory system.

This method reduces the risk of human error and speeds up the counting process significantly. Even without specialized software, businesses can use basic barcode or QR code scanners, which are affordable and easy to use.

When you scan these codes, your employees can quickly update inventory records without the need for manual data entry.

Yes, it clearly enhances productivity!

Simplifying the process through scanning is not something that is too complex to accomplish as you think. It helps businesses to maintain precise inventory records and provide better service to customers.

You need robust inventory management software for several reasons.

As the initial step, it significantly reduces the chances of errors compared to manual methods, ensuring accurate inventory records. Plus, it expedites the entire small business stock controls, from counting to reordering, saving time and increasing efficiency.

On the one hand, inventory software offers real-time insights into stock levels. This encourages businesses to make informed decisions promptly. On the other hand, it enhances organization by categorizing items, generating reports, and tracking inventory movement seamlessly.

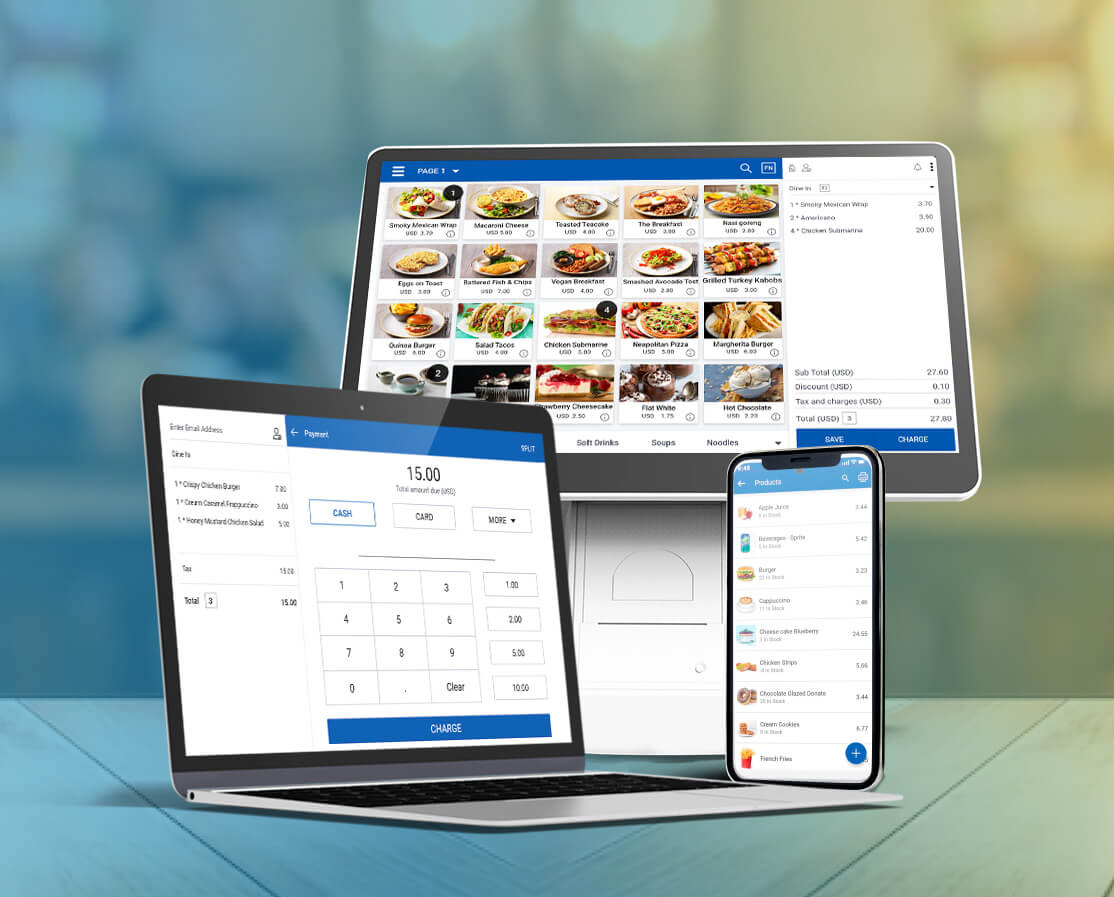

Considering the competitiveness in today’s business world, implementing the best pos software for small business with inventory software will help you remain competitive among other companies. It simplifies operations, minimizes costs, and optimizes inventory control, ultimately contributing to improved productivity and profitability for your small business by taking your small business to the next level.

Since you have read the full article, you may understand how important it is to perform inventory counts within your store on a regular basis.

With the right arm to help you, you can go a long way if you take full control of your inventory.

Start improving your small business inventory management today by implementing these inventory counting strategies!

Keep Counting on Success with SalesPlay

Ever wondered how to stand out in a crowded market? Check out this awesome YouTube video by Brian Tracy, "7 Strategies to Grow Your Business." In just a few minutes, Tracy breaks down some fantastic tips to help your business thrive. His insights are super helpful and easy to understand, so give it a watch and get ready to see your business rise!

The best way to count inventory depends on your business size and needs, but accuracy and efficiency should be top priorities.

A well-organized system and the right tools can make counting inventory easier, faster, and much more accurate!

The golden rule for inventory is simple: “Stock what you sell, and sell what you stock.” It’s all about balance!

If you overstock, your cash gets stuck in unsold items, leading to wasted space and possible losses. On the other hand, understocking means frustrated customers and lost sales—nobody likes hearing, “Sorry, we’re out of stock!”

To follow the golden rule effectively, track your sales trends and adjust inventory accordingly. A good inventory management system helps you maintain just the right amount—enough to meet demand without overflowing shelves.

Also, FIFO (First In, First Out) is a must, especially for perishable goods. Sell the oldest stock first to avoid waste!

Lastly, regular inventory checks help you stay on top of things. Whether it’s weekly, monthly, or annually—just don’t let dust settle on forgotten products!

Stick to this golden rule, and you’ll have happy customers, optimized storage, and a business that runs smoothly!

Inventory is the backbone of any business, keeping things running smoothly. It falls into four main categories:

Understanding these categories helps businesses manage stock better, avoid shortages, and keep customers happy.

The best inventory method for a small business depends on the type of products and how often they sell. But don’t worry—I’ll break it down simply!

For most small businesses, FIFO or JIT usually works best. Choose the method that fits your business needs and keeps things running smoothly